Does this kit offer clear installation instructions and video support?

Your kit should include straightforward instructions with detailed images that highlight potential trouble spots. For many installers, video walkthroughs are even more effective, making it easy for anyone—regardless of experience—to get up to speed quickly.

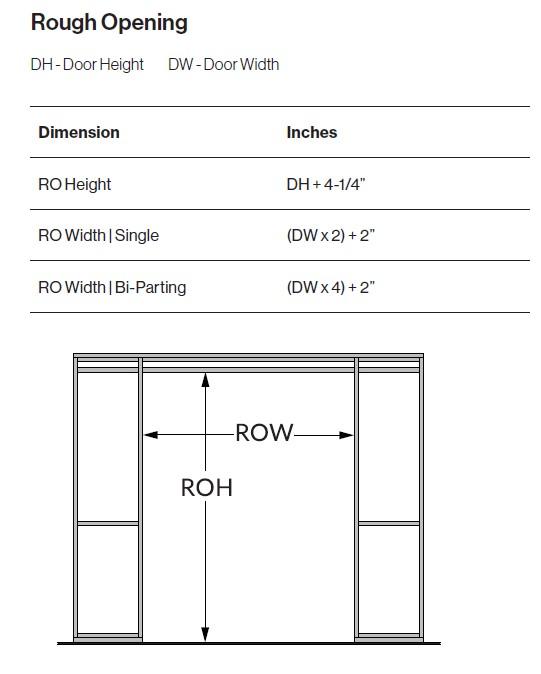

If you are using the CS Cavity Sliders pocket frame kit, make sure the service notch on the track butts up to the closing jamb, NOT the back stud.

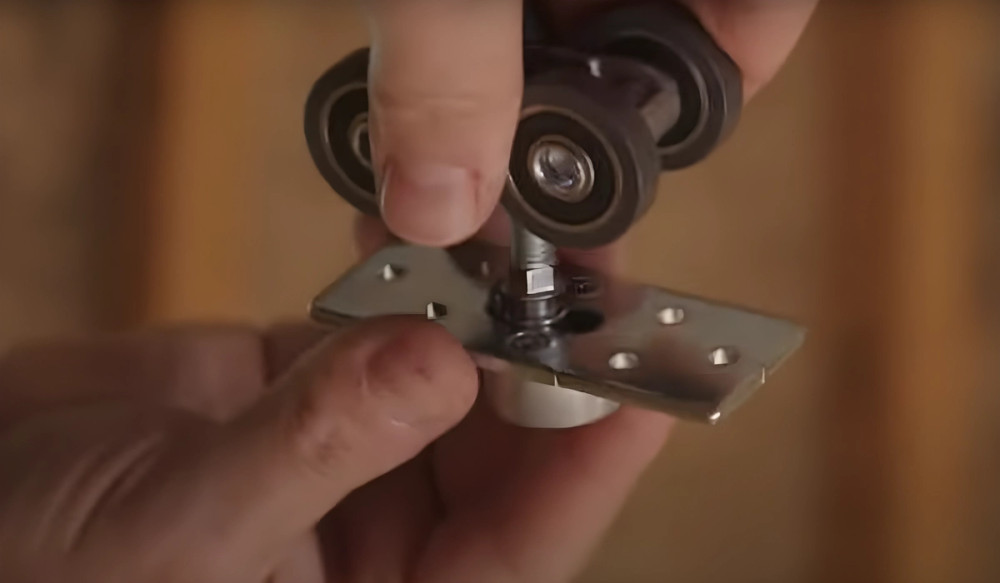

Watch the video below for assembly instructions, starting at 1:35.

Assemble and install the CS Cavity Slider Pocket Door Frame by securing the track, attaching the frame to the wall studs, fitting the door brackets, and ensuring alignment for smooth sliding operation.